- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

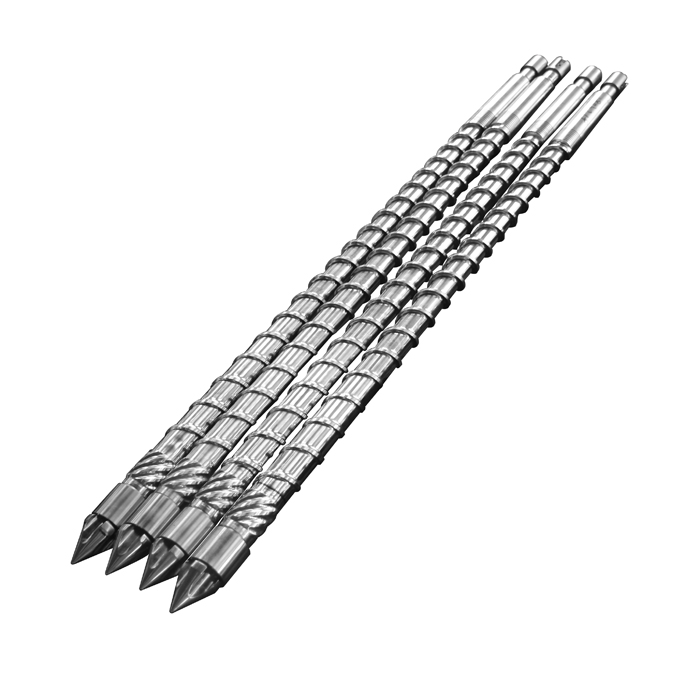

Injection Molding Screw Barrel

With different driving systems, injection molding machines are divided into three types:

1) Hydraulic injection molding machine

2) Electric injection molding machine

3) Mechanical injection molding machine

EJS factory manufactures injection molding screw barrels for all three types of injection molding machine, supplied for Haitian, Negri Bossi injection molding machines.

Send Inquiry

Injection molding screw barrel

Each member from our company highly values customers' needs. To get China Bimetallic Injection Molding Machine Screw Barrel, you are warmly welcome to contact us for pricing, to get your project started, our team will do the rest for you.

One taste can’t please all. One material can’t work for all applications either, therefore we select a number of other steels to produce screws and barrels for best performances at best costs, this include injection molding machine barrel.

Other than this, E.J.S produces screw and barrel for injection molding machine and injection screw and barrel for customers natioanlly and internationally and always stand behind the products we produce and provide long term support for our products.

With different driving systems, injection molding machines are divided into three types:

1) Hydraulic injection molding machine

2) Electric injection molding machine

3) Mechanical injection molding machine

EJS factory manufactures injection molding screw barrels for all three types of injection molding machine, supplied for Haitian, Negri Bossi injection molding machines.

Bore diameter available for Injection molding screw barrel

¢16~¢220

Popular Materials used for Injection molding screw barrel

38CrMoAlA (DIN1.8509)

34CrAlNi7 (DIN1.8550)

31CrMoV9 (DIN1.8519)

40Cr (AISI 4340)

42CrMo ( AISI4140)

SKD61

SKD61 hardfacing

D2 ( Din1.2379)

Surface Treatment of Injection molding screw barrel

Full body nitrided

Quenching

Bimetallic alloy coating

Different percentage of glass fiber added, different bimetallic type could be chosen

Application of Injection molding screw barrel

EJS injection molding screw barrels has been contributing their experience and expertise to injecting molding machines in various fields like below:

Automotive(switch buttons, screens, water pump housing...)

Packaging(food container, flower pots, drinking cups, flap closures...)

Medical(masks, blood meters, protection glasses, syringes...)

Electronics(connectors, fuse box, cell phone cases, battery housing, screen monitor...)

Logistics(waste container, storage box, buckets, pip fittings...)

Consumer goods(Toys, dowels, pen housings, toothbrushers, razors, cable ties...)

White goods(housings and functional parts for washing machines, refreigerators, freezers, air conditioners...)

What are top five manufacturers for injection moulding machines?

They are Haitian International, ARBURG, ENGEL, Husky Injection Molding Systems,Sumitomo Demag.

EJS has been lucky to have been producing injection molding screw barrel for all these machines, please be free to contact your EJS agent for further communication.

About E.J.S.

EJS Screw Barrels is a newly created brand name for Export business with manufacturing experiences since 1992.

A screw barrel manufacturer dedicated on producing customized screw barrel and design extruder screw barrels, injection moulding screw barrels.

Bimetallic Screw Barrels

We started to make bimetallic screw barrel at a very early age, almost the same time as the first bimetallic barrel was born in China. Now we have several types for options depending on different applications

|

Bimetallic Barrels |

|||||

|

Alloy Type |

EJS01 Alloy |

EJS02 Alloy |

EJS03 Alloy |

EJS04 Alloy |

|

|

Alloy Components |

Fe+Ni+Cr+B |

Ni+Cr+Co+B |

Ni+Cr+Co+V+B |

Ni+Wc+Cr+B |

|

|

Wearing Resistance |

★★★ |

★★ |

★★★ |

★★★★ |

|

|

Corrosion Resistance |

★★ |

★★★ |

★★★ |

★★★ |

|

|

Alloy Thickness |

2~3mm |

1.5~2mm |

1.5~2mm |

1.5~2mm |

|

|

Hardness |

HRC 58-65 |

HRC 50-58 |

HRC 55-60 |

HRC 55-65 |

|

|

Temperature Range |

≤400 |

≤450 |

≤450 |

≤600 |

|

|

Coefficient Thermal |

RT~250℃ |

11.0x10-6 |

11.0x10-6 |

11.5x10-6 |

11.0x10-6 |

|

Expansion(/℃) |

RT~400℃ |

11.4x10-6 |

11.4x10-6 |

12.4x10-6 |

12x10-6 |

|

Range of Workable Length |

700mm~3000mm/piece |

||||

|

Base Steel Vastly Used |

40Cr: 42CrMo |

||||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||||

|

Bimetallic Screws |

|||

|

Suitable for |

Single Screw, Twin Parallel Screw, Twin Conical Screw |

||

|

Alloy Type |

Ni60 |

CoImonoy 56 |

CoImonoy 83 |

|

Alloy Components |

Ni+Cr+Fe+Si |

Ni+Cr+Si+Fe |

Ni+Wc+Cr+C |

|

Anti-Wearing Level |

★★★ |

★★★ |

★★★★ |

|

Anti-Corrosion Level |

★★★★ |

★★★★ |

★★★★ |

|

Alloy Thickness |

1~1.5mm |

1~1.5mm |

1~1.5mm |

|

Hardness |

HRC 56-62 |

HRC 46~61 |

HRC 43-48 |

|

Applied Glass Fiber |

Under 10% |

|

|

|

Range of Workable Length |

Any length needed |

||

|

Base Steel Vastly Used |

38CrMoAI(1.8509), 34CrAINi7(1.8550), 31CrMoV9(1.8519) |

||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||

Quality Inspection

Quality is a very important step during production. For making a quality screw barrel, all tolerances should be fulfilled and all dimensions should be correct and put in records.

We provide inspection report, material certificate for every of our supplied screw barrels.

Packaging

Packaging is the last but very important step before shipping. A strong and smart packing box is also part of our quality. It is not only used to protect the screws barrels well during transportation, also provide an easy way for our customer to unpack.