- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

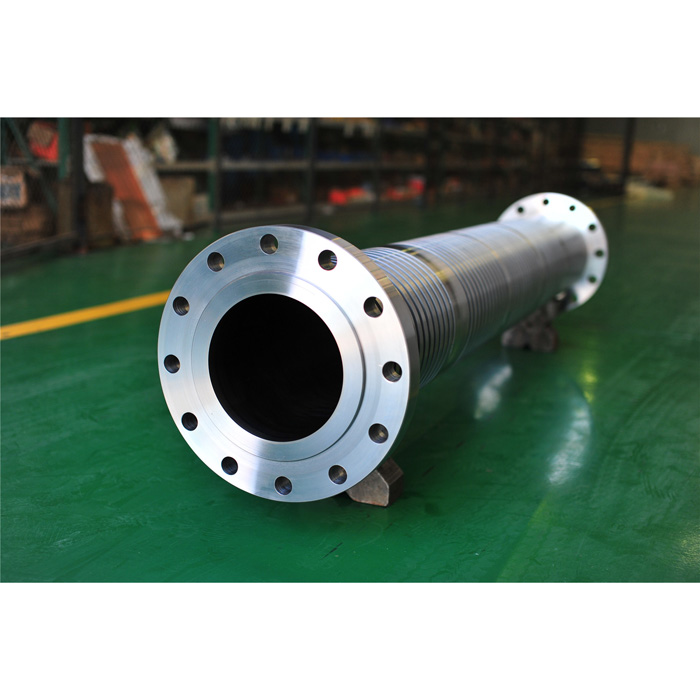

Plastic Recycling Extruder Screw Barrel

When plastics make our life easier, they also bring us enormous wastes as well as pollution. Plastic recycling is essential and critical to make our earth greener. Fortunately EJS is cooperating with some plastic recycling extruder people by producing Plastic recycling extruder screw barrel, to contribute our dedication and expertise to our better earth for our next generations.

Send Inquiry

Plastic recycling extruder screw barrel

Plastic Recycling extruder is very popular and very much environmental-friendly. Too much plastics will give our earth too much burden, and we can’t live a normal daily life without plastics. Therefore, recycling is the future. China Recycling screw barrels are produced with large quantities nowadays.

The recycled material has a higher request on the screw barrel, as they give more wearing on the screw barrel. Not only the design is special for recycling extruder, also we need to make bimetallic barrel and hardfacing screws. to have a proper life time.

When plastics make our life easier, they also bring us enormous wastes as well as pollution.

Plastic recycling is essential and critical to make our earth greener.

Fortunately EJS is cooperating with some plastic recycling extruder people by producing Plastic recycling extruder screw barrel, to contribute our dedication and expertise to our better earth for our next generations.

EJS is a professional manufacturer of Bimetallic Barrels, Extrusion Barrel for years, with customers of OEM machine builders as well as end users.

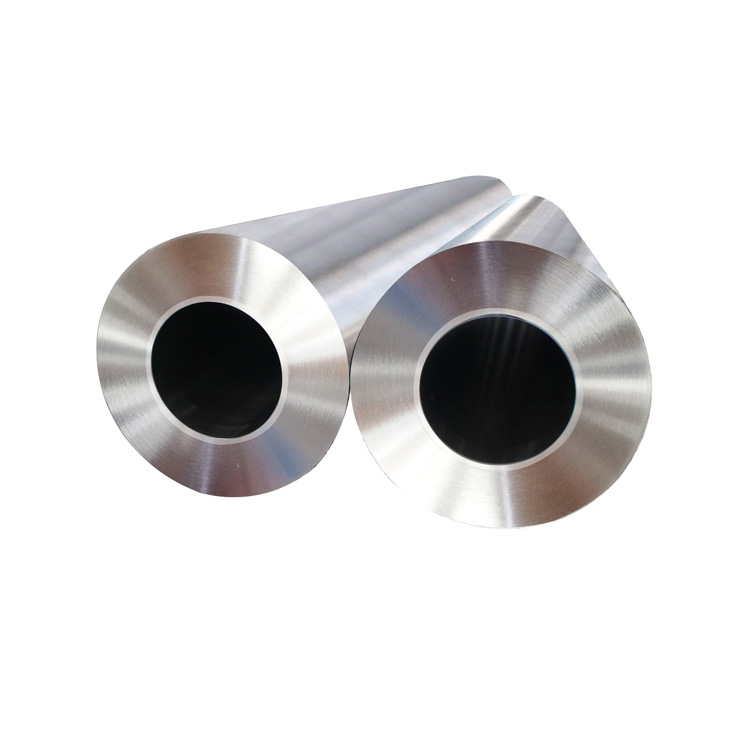

Bore diameter available for plastic recycling extruder screw barrel

¢16~¢500

Popular Materials used for plastic recycling extruder screw barrel

38CrMoAlA(1.8509)

34CrAlNi7(1.8550)

31CrMoV9(1.8519)

40Cr(4340)

42CrMo(4140)

SKD11

Alloy powder of plastic recycling extruder screw barrel

Kennametal Stellite Ni60

Colmonoy 56

Colmonoy 83

EJS01 alloy

EJS04 alloy

Application of plastic recycling extruder screw barrel

Single screw barrel

Twin screw barrel

How can I go to your factory? I have never visited China before. Can you help me on the transportation and hotels?

A trip to China is not difficult, EJS will help you to make the whole trip easier by a good preparation in advance:

1) China Visa: EJS will issue an Invitation Letter for your visit, then you could contact China Embassy in your country for visa application, or get an agent to help.

2) Flight tickets: we have international airports nearby, Ningbo, Hangzhou, Shanghai; If you fly to Beijing( Peking, our capital city), then a domestic flight to Ningbo is needed.

3) Hotels: we will book the hotels for you in advance, in our city Ningbo, 5-star hotels are available, such as ShangriLa, Marriot, Crown Plaza, just be free to tell us what you like, we’ll find you a good home.

4) Local transportation: we will arrange the airport pickup and airport drive-away, as well as factory visit.

5) Food: Ningbo is very international, a big selection of food is possible.

In a word, we’ll make your travelling safe and convenient, EJS staff is not only good at screw barrel production, but also good at China trips.

About E.J.S.

EJS Screw Barrels is a newly created brand name for Export business with manufacturing experiences since 1992.

A screw barrel manufacturer dedicated on producing customized screw barrel and design extruder screw barrels, injection moulding screw barrels.

Bimetallic Screw Barrels

We started to make bimetallic screw barrel at a very early age, almost the same time as the first bimetallic barrel was born in China. Now we have several types for options depending on different applications

|

Bimetallic Barrels |

|||||

|

Alloy Type |

EJS01 Alloy |

EJS02 Alloy |

EJS03 Alloy |

EJS04 Alloy |

|

|

Alloy Components |

Fe+Ni+Cr+B |

Ni+Cr+Co+B |

Ni+Cr+Co+V+B |

Ni+Wc+Cr+B |

|

|

Wearing Resistance |

★★★ |

★★ |

★★★ |

★★★★ |

|

|

Corrosion Resistance |

★★ |

★★★ |

★★★ |

★★★ |

|

|

Alloy Thickness |

2~3mm |

1.5~2mm |

1.5~2mm |

1.5~2mm |

|

|

Hardness |

HRC 58-65 |

HRC 50-58 |

HRC 55-60 |

HRC 55-65 |

|

|

Temperature Range |

≤400 |

≤450 |

≤450 |

≤600 |

|

|

Coefficient Thermal |

RT~250℃ |

11.0x10-6 |

11.0x10-6 |

11.5x10-6 |

11.0x10-6 |

|

Expansion(/℃) |

RT~400℃ |

11.4x10-6 |

11.4x10-6 |

12.4x10-6 |

12x10-6 |

|

Range of Workable Length |

700mm~3000mm/piece |

||||

|

Base Steel Vastly Used |

40Cr: 42CrMo |

||||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||||

|

Bimetallic Screws |

|||

|

Suitable for |

Single Screw, Twin Parallel Screw, Twin Conical Screw |

||

|

Alloy Type |

Ni60 |

CoImonoy 56 |

CoImonoy 83 |

|

Alloy Components |

Ni+Cr+Fe+Si |

Ni+Cr+Si+Fe |

Ni+Wc+Cr+C |

|

Anti-Wearing Level |

★★★ |

★★★ |

★★★★ |

|

Anti-Corrosion Level |

★★★★ |

★★★★ |

★★★★ |

|

Alloy Thickness |

1~1.5mm |

1~1.5mm |

1~1.5mm |

|

Hardness |

HRC 56-62 |

HRC 46~61 |

HRC 43-48 |

|

Applied Glass Fiber |

Under 10% |

|

|

|

Range of Workable Length |

Any length needed |

||

|

Base Steel Vastly Used |

38CrMoAI(1.8509), 34CrAINi7(1.8550), 31CrMoV9(1.8519) |

||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||

Quality Inspection

Quality is a very important step during production. For making a quality screw barrel, all tolerances should be fulfilled and all dimensions should be correct and put in records.

We provide inspection report, material certificate for every of our supplied screw barrels.

Packaging

Packaging is the last but very important step before shipping. A strong and smart packing box is also part of our quality. It is not only used to protect the screws barrels well during transportation, also provide an easy way for our customer to unpack.