- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

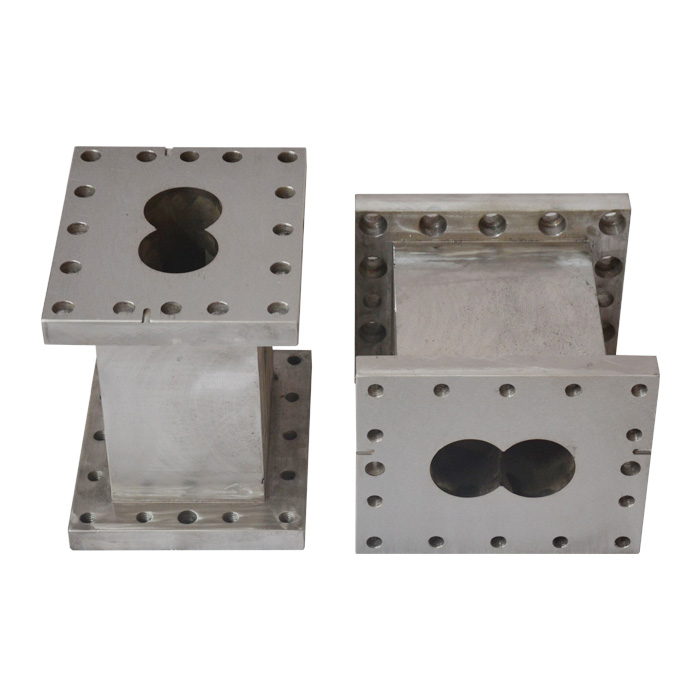

Segment Twin Screw Barrel

Masterbatch (MB) is a solid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch). A liquid dosage form is called liquid color. Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to color raw polymer economically during the plastics process.Welcome to buy Segment Twin Screw Barrel from us.

Send Inquiry

Segment twin screw barrel

We are proud of “making your screw barrel business Easier with Joys and Success”.

OEM & ODM Manufacturer E.J.S of China Segment Twin Screw Barrel, "Emphasize details, Pursue excellence" is definitely the philosophy of our company. We sincerely invite you to talk with EJS sales team and discuss the business and cooperation together!

OEM & ODM Manufacturer China Segment Twin Screw Barrel, Plastic Twin Screw Extruder Screw Element, we have a professional team, they have mastered the best knowledge and technology and manufacturing processes, they ave years of experience in working with customers from different countries, fluent English helps to communicate seamlessly and accurately to understand the customers needs correctly, providing customers with personalized service and unique products.

Masterbatch (MB) is a solid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch). A liquid dosage form is called liquid color. Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to color raw polymer economically during the plastics process.

At EJS, we produce segment twin screw barrel for masterbatch extruders. EJS is a professional manufacturer of Extruder Screw Elements for years, with customers of OEM machine builders as well as end users.

Bore diameter available for Segment twin screw barrel

¢12~¢350

Popular Materials used for Segment twin screw barrel

38CrMoAlA(1.8509)

Steel 45

W6Mo5Cr4V2

40CrNiMoA

40Cr

HYM4

Surface Treatment of Segment twin screw barrel

Full body nitrided

Bimetallic carbide liner for twin parallel barrels

Bimetallic alloy coating for twin parallel screws

Segment twin screw barrel making masterbatch serves in the following areas:

Blown film & lamination

PP raffia/Yarn

PP non-woven fabric

Blow molding

Injection molding

Thermoformed sheet

HDPE/PP pipe extrusion

Polyester and Nylon yarn

Fiber extrusion

Profile extrusion

Tube extrusion

Segment twin screw barrel working on various masterbatch extruders

Color masterbatch

Additive masterbatch

Filler masterbatch

I am very busy, I don’t have time to visit your factory, how can we meet?

When a face-to-face meeting is the best, at our factory, or at your company, we can also meet at big exhibitions like NPE, K-Show, InterPlastica Russia, ChinaPlas; we can even have a video phone call. Therefore talking together in time, meeting together face to face should not be an obstacle for our communication and cooperation.

About E.J.S.

EJS Screw Barrels is a newly created brand name for Export business with manufacturing experiences since 1992.

A screw barrel manufacturer dedicated on producing customized screw barrel and design extruder screw barrels, injection moulding screw barrels.

Bimetallic Screw Barrels

We started to make bimetallic screw barrel at a very early age, almost the same time as the first bimetallic barrel was born in China. Now we have several types for options depending on different applications

|

Bimetallic Barrels |

|||||

|

Alloy Type |

EJS01 Alloy |

EJS02 Alloy |

EJS03 Alloy |

EJS04 Alloy |

|

|

Alloy Components |

Fe+Ni+Cr+B |

Ni+Cr+Co+B |

Ni+Cr+Co+V+B |

Ni+Wc+Cr+B |

|

|

Wearing Resistance |

★★★ |

★★ |

★★★ |

★★★★ |

|

|

Corrosion Resistance |

★★ |

★★★ |

★★★ |

★★★ |

|

|

Alloy Thickness |

2~3mm |

1.5~2mm |

1.5~2mm |

1.5~2mm |

|

|

Hardness |

HRC 58-65 |

HRC 50-58 |

HRC 55-60 |

HRC 55-65 |

|

|

Temperature Range |

≤400 |

≤450 |

≤450 |

≤600 |

|

|

Coefficient Thermal |

RT~250℃ |

11.0x10-6 |

11.0x10-6 |

11.5x10-6 |

11.0x10-6 |

|

Expansion(/℃) |

RT~400℃ |

11.4x10-6 |

11.4x10-6 |

12.4x10-6 |

12x10-6 |

|

Range of Workable Length |

700mm~3000mm/piece |

||||

|

Base Steel Vastly Used |

40Cr: 42CrMo |

||||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||||

|

Bimetallic Screws |

|||

|

Suitable for |

Single Screw, Twin Parallel Screw, Twin Conical Screw |

||

|

Alloy Type |

Ni60 |

CoImonoy 56 |

CoImonoy 83 |

|

Alloy Components |

Ni+Cr+Fe+Si |

Ni+Cr+Si+Fe |

Ni+Wc+Cr+C |

|

Anti-Wearing Level |

★★★ |

★★★ |

★★★★ |

|

Anti-Corrosion Level |

★★★★ |

★★★★ |

★★★★ |

|

Alloy Thickness |

1~1.5mm |

1~1.5mm |

1~1.5mm |

|

Hardness |

HRC 56-62 |

HRC 46~61 |

HRC 43-48 |

|

Applied Glass Fiber |

Under 10% |

|

|

|

Range of Workable Length |

Any length needed |

||

|

Base Steel Vastly Used |

38CrMoAI(1.8509), 34CrAINi7(1.8550), 31CrMoV9(1.8519) |

||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||

Quality Inspection

Quality is a very important step during production. For making a quality screw barrel, all tolerances should be fulfilled and all dimensions should be correct and put in records.

We provide inspection report, material certificate for every of our supplied screw barrels.

Packaging

Packaging is the last but very important step before shipping. A strong and smart packing box is also part of our quality. It is not only used to protect the screws barrels well during transportation, also provide an easy way for our customer to unpack.