- English

- 简体中文

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

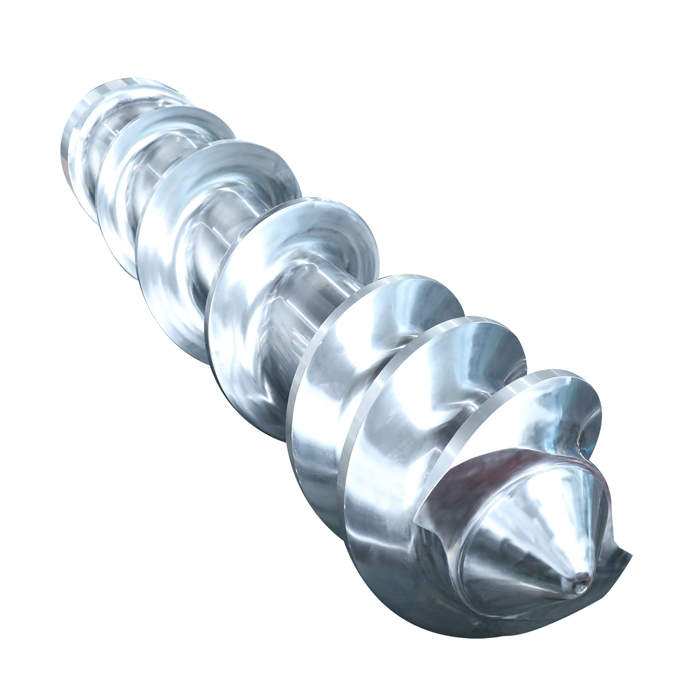

Pin Rubber Extrusion Screw and Barrel

Pin Rubber Extrusion Screw and Barrel is mainly used for shaping extrusions of various of rubber pipe, tread,cable and others from rubber compounds at room temperature. EJS produces PIN barrel extruder screw and barrel for leading players in the rubber field.

Send Inquiry

PIN barrel extruder screw and barrel

Pin Rubber Extrusion Screw and Barrel is mainly used for shaping extrusions of various of rubber pipe, tread,cable and others from rubber compounds at room temperature. EJS produces PIN barrel extruder screw and barrel for leading players in the rubber field.When people walk with two legs, EJS has other groups of screw and barrel as well, such as rubber screw. This expands our product range, keeps our 400 colleagues busy, most importantly it makes customers work easier.

Bore diameter available for PIN barrel extruder screw and barrel

60 ~ 250mm

L/D ratio for PIN barrel extruder screw and barrel

Varies from 15D to 20D

Surface Treatment of PIN barrel extruder screw and barrel

Nitrided

Hard Chrome Plating

Ceramic coated

Hardfacing / Bimetallic with Ni60, Colmonoy 56, Colmonoy 83

Quenching

Material request for PIN barrel extruder screw and barrel

The material for rubber screw must be:

Anti-high temperature;

Anti-wearing;

Anti-corrosion;

High strength to work with high torque and high speed;

Good cutting performance;

The relief and the thermal deformation is small after heat treatment.

The material for PIN barrel extruder screw and barrel include:

38CrMoAlA (DIN1.8509)

42CrMo ( AISI4140)

Stainless steel 304

Main features of pin cold feed extruder:

1. The barrel is made with several sections and spiral grooves in feeding section. With feed roller, with certain pins on plasticizing zone and extrusion zone, feeding capacity is largely increased.

2. The temperature of each zone is automatically controlled respectively per sections by the hot water circulation device;

3. Top advantages of pin cold feed extruder: excellent plasticizing, higher extrusion capacity, lower temperature of end products, less machine-down;

4. PIN barrel extruder screw and barrel made by EJS, produced by CNC milling machine, are with high precision and great anti-wearing ability.

Application of pin cold feed extruder

The pin type cold feed extruder is made by installing several rows of pins on a certain part of the screw or barrel. The pin type cold feed extruder has different types such as pin screw extruder, pin barrel extruder, pin main/barrier-flight pin screw extruder, pin-transferring extruder.

Pin-type cold feed extruder is mainly used for shaping and extruding various parts such as treads in tire production, rubber tubes, rubber sheets, conveyor belt core and cover; Continuous coating of wires, cables, hoses and other products; rubber supply to calendar machines to replace open mills.

About E.J.S.

EJS Screw Barrels is a newly created brand name for Export business with manufacturing experiences since 1992.

A screw barrel manufacturer dedicated on producing customized screw barrel and design extruder screw barrels, injection moulding screw barrels.

Bimetallic Screw Barrels

We started to make bimetallic screw barrel at a very early age, almost the same time as the first bimetallic barrel was born in China. Now we have several types for options depending on different applications

|

Bimetallic Barrels |

|||||

|

Alloy Type |

EJS01 Alloy |

EJS02 Alloy |

EJS03 Alloy |

EJS04 Alloy |

|

|

Alloy Components |

Fe+Ni+Cr+B |

Ni+Cr+Co+B |

Ni+Cr+Co+V+B |

Ni+Wc+Cr+B |

|

|

Wearing Resistance |

★★★ |

★★ |

★★★ |

★★★★ |

|

|

Corrosion Resistance |

★★ |

★★★ |

★★★ |

★★★ |

|

|

Alloy Thickness |

2~3mm |

1.5~2mm |

1.5~2mm |

1.5~2mm |

|

|

Hardness |

HRC 58-65 |

HRC 50-58 |

HRC 55-60 |

HRC 55-65 |

|

|

Temperature Range |

≤400 |

≤450 |

≤450 |

≤600 |

|

|

Coefficient Thermal |

RT~250℃ |

11.0x10-6 |

11.0x10-6 |

11.5x10-6 |

11.0x10-6 |

|

Expansion(/℃) |

RT~400℃ |

11.4x10-6 |

11.4x10-6 |

12.4x10-6 |

12x10-6 |

|

Range of Workable Length |

700mm~3000mm/piece |

||||

|

Base Steel Vastly Used |

40Cr: 42CrMo |

||||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||||

|

Bimetallic Screws |

|||

|

Suitable for |

Single Screw, Twin Parallel Screw, Twin Conical Screw |

||

|

Alloy Type |

Ni60 |

CoImonoy 56 |

CoImonoy 83 |

|

Alloy Components |

Ni+Cr+Fe+Si |

Ni+Cr+Si+Fe |

Ni+Wc+Cr+C |

|

Anti-Wearing Level |

★★★ |

★★★ |

★★★★ |

|

Anti-Corrosion Level |

★★★★ |

★★★★ |

★★★★ |

|

Alloy Thickness |

1~1.5mm |

1~1.5mm |

1~1.5mm |

|

Hardness |

HRC 56-62 |

HRC 46~61 |

HRC 43-48 |

|

Applied Glass Fiber |

Under 10% |

|

|

|

Range of Workable Length |

Any length needed |

||

|

Base Steel Vastly Used |

38CrMoAI(1.8509), 34CrAINi7(1.8550), 31CrMoV9(1.8519) |

||

|

Mark in the list: ★★★★ Excellent; ★★★ Very Good; ★★Good |

|||

Quality Inspection

Quality is a very important step during production. For making a quality screw barrel, all tolerances should be fulfilled and all dimensions should be correct and put in records.

We provide inspection report, material certificate for every of our supplied screw barrels.

Packaging

Packaging is the last but very important step before shipping. A strong and smart packing box is also part of our quality. It is not only used to protect the screws barrels well during transportation, also provide an easy way for our customer to unpack.